Global

Global

Welcome!

For an optimal price and logistics experience log in or register to order at Micro Hybrid:

Register

Create new accountPassword forgotten? Please continue here to reset your password

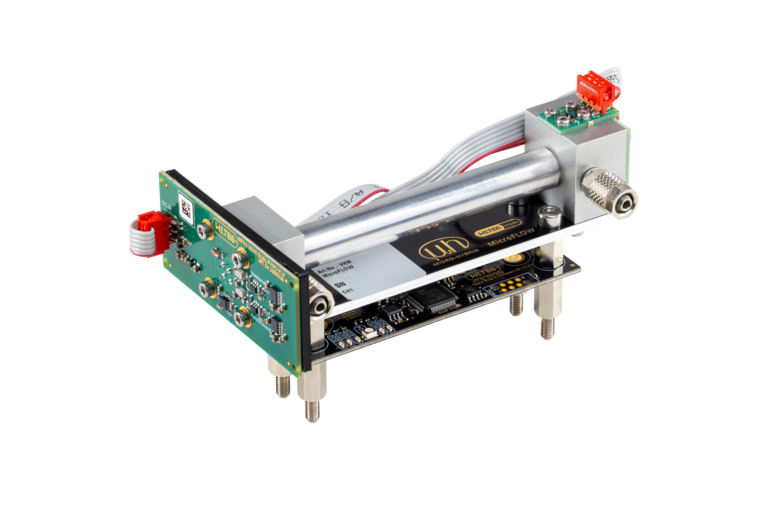

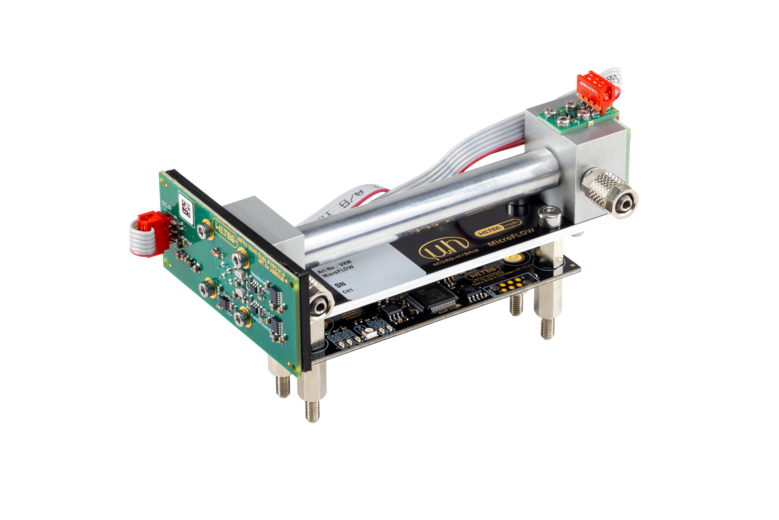

MicroFLOW CH4 . select 10 Vol.-%

Inline NDIR gas sensor for selective measurement of methane up to 10 vol%.

- Very high measuring accuracy: < 1 % max. deviation

- High long-term stability thanks to NDIR dual-beam method

- Pressure compensation through integrated pressure sensor in the cell block

- Digital interfaces RS232/ CAN-Bus integrated as standard

- Cell optimized for CH4 sample gas in the measuring range up to 10 % by volume

Bulk prices

| starting from 1 | 964,71 € |

| starting from 10 | 699,35 € |

| starting from 25 | 670,25 € |

| starting from 50 | 636,86 € |

Details

You are currently ordering as a guest. To enjoy all the benefits of our Plattform such as higher quantities, customized prices, inventory, tracking (order status), order overview or change of repository etc. please log in to My Micro Hybrid

Description

The MicroFLOW CH4 .select 10 Vol.-% sensor is suitable for a wide range of demanding applications that require precision and reliability.

FIELDS OF APPLICATION

Environmental technology: In composting plants, the analysis of methane is important to monitor the anaerobic decomposition process. Methane is a significant by-product of this process and serves as an indicator of the efficiency of the plant. Continuous monitoring makes it possible to optimize process parameters, control operations and ensure that the plant operates in compliance with environmental regulations. Precise measurement of methane concentrations in biogas plants enables targeted adjustment of process conditions to ensure maximum gas yield.

Industry: In petrochemical plants for the further processing of fossil raw materials, fast and precise detection of leaks ensures that potentially dangerous methane leaks are detected at an early stage. Furthermore, the MicroFLOW CH4 .select 10 Vol.-% can be used to test the quality and purity of natural gas in order to comply with methane content specifications.

Plant cultivation: Methane is an indicator of biological activity in the soil but also a greenhouse gas. CH4 is monitored because it can influence plant growth in the soil atmosphere. By accurately measuring methane concentrations, environmental impacts can also be assessed and measures taken to reduce emissions.

MEASUREMENT ACCURACY

Our NDIR gas sensor achieves precise results for the selective measurement of methane without cross-sensitivity to other hydrocarbons. The IR detector in the sensor uses the absorption band of CH4 of 7.5 to 8 µm for this purpose. Thanks to 10-point linearization, the maximum deviation of the measured gas concentration is less than one percent over the entire measuring range up to 10 % by volume.

The sensor reliably detects minimal gas concentrations in order to recognize even the smallest changes in the gas mixture. You can freely select your application measuring range (e.g. 1 vol.-%) within the entire measuring range (0 to 10 vol.-%).

Measurement deviations due to pressure fluctuations or barometric changes are compensated for using the µP.sens pressure sensor in the cuvette block (< 0.1 % / 10 hPa). Leakages and falsification of measured values are excluded. The integration of the pressure sensor in the cuvette block helps to reduce the space requirement of the overall module compared to comparable sensors.

Temperature compensation is guaranteed for each sensor module. Each module is tested and calibrated in the climate chamber by recording and correcting the error curve during measurement with a test gas at a specified concentration. The test and correction are carried out at zero point and end point as well as at other typical temperatures within the sensor's operating range of 5 - 45 °C. The maximum deviation is less than one third. The maximum deviation is less than 1 % per 10 K.

RANGE OF FUNCTIONS

With the digital interfaces RS232 and CAN bus, the interfaces most commonly used in industry are available ex works. You can select the interface for your individual setting with the optional accessories and the MARSlight software. To do this, follow the instructions in the software manual.

The cuvette is optimized for methane in the measuring range of up to 10 % by volume.

In contrast to conventional sensors, our sensor enables measurements in a wide pressure range of 300 - 1200 hPa. This opens up an extended range of applications, e.g. for applications in higher geographical locations or for systems that work with negative pressure.

LIFETIME

The gas connection blocks made of anodized aluminium with high chemical resistance guarantee a long service life and reliability under demanding conditions. The stainless steel gas connections also ensure durability.

Premature component failures are ruled out by climate chamber tests in the operating temperature range.

INSTALLATION AND OPERATION

The MARS light software specially developed for the gas sensors is available to download free of charge. This means your gas sensor is ready for immediate use. You save project time as you do not have to develop your own software for initial test measurements. The sensor is characterized by a low power consumption of less than 1 watt. This allows it to be used in battery-operated devices. The wide voltage range of 9 to 30 volts allows easy integration into most existing systems.

Depending on the application, gases sometimes need to be pre-cooled or heated before the actual analysis. Possible condensation effects of the gas in the cuvette are prevented by monitoring the gas temperature in the measuring system.

In contrast to many comparable products, cleaning and any maintenance can be carried out with little effort thanks to the modular design.

All information on commissioning and operation can be found in the manual.

You will find a clear summary of the most important technical details in our data sheet. We will be happy to advise you on individual questions and requirements.

Technical Data

| Measuring principle | NDIR |

| Cuvette length | 100 mm |

| Estimated operating life | 40000 h |

| Gas flow rate | 0,1 - 2 l/min |

| Height | 71 mm |

| Width | 139 mm |

| Depth | 69.5 mm |

| Weight | 170 |

| Hose connections | |

| Electrical connection type | |

| Communication connection type | |

| Maximum measuring range | 10 Vol.-% |

| Warm-up time | < 10 min |

| Response time | < 2 s |

| Detection limit | < 0,1 % FS |

| Digital resolution | 0.001 Vol.-% |

| Linearity error | < 0,6 % FS |

| Repeatability | < 0,2 % FS |

| Zero-point long-term stability | < 3 % FS / month |

| End-point long-term stability | < 3 % FS / month |

| Zero-point temperature influence | < 0,4 % FS / 10 K |

| End-point temperature influence | < 0,5 % FS / 10 K |

| Position dependence | < 0,5 % FS / 180° |

| Pressure influence | < 0,01 % FS / 10hPa |

| Operating voltage | 9 - 30 V DC |

| Maximum operating current | 45 mA |

| Nominal power consumption | 1 W |

| Electrical connection type (communication) | |

| Output format (CAN) | MARS/ CANopen |

| Output format (RS232) | ASCII |

| Maximum data rate (CAN) | 10 ms |

| Maximum data rate (RS232) | 100 ms |

| Minimum operating temperature | 5 °C |

| Maximum operating temperature | 45 °C |

| Minimum storage temperature | -20 °C |

| Maximum storage temperature | 60 °C |

| Minimum air pressure | 300 hPa |

| Maximum air pressure | 1,200 hPa |

| Humidity (environment) |

0 ... 95 % relative humidity (non condensing)

|

| Measuring gas | methane (CH4) |

| Digital output signal |

RS232

CAN-Bus

|